Fabrication

Our team of highly qualified tradesmen and welders have the experience and knowledge to meet your requirements and all relevant codes.

Advanced equipment

Our welding equipment features the latest technology, including flux core, RMD and STT. Welding processes such as SMAW, FCAW, GMAW, SAW and GTAW are also available and stainless and aluminium welding can also be undertaken.

Quality

Our workshop is certified by Telarc to ISO 9001 and along with our in-house QA/QC procedures, you can have confidence in the manufacturing process.

Welding work is carried out in accordance with ASME IX AWS D1.1 and AS/NZS 1554.1.

Pressure vessel construction is carried out to BS5500 or ASME VIII standards, and construction of pipework, including geothermal and petrochemical lines, is carried out to the requirements of ASME B31.1 and B31.3.

Workshop facilities

Our Fabrication Workshop has the capability to undertake:

Subarc Welding

Plate Rolling

Furnace Stress Relieving

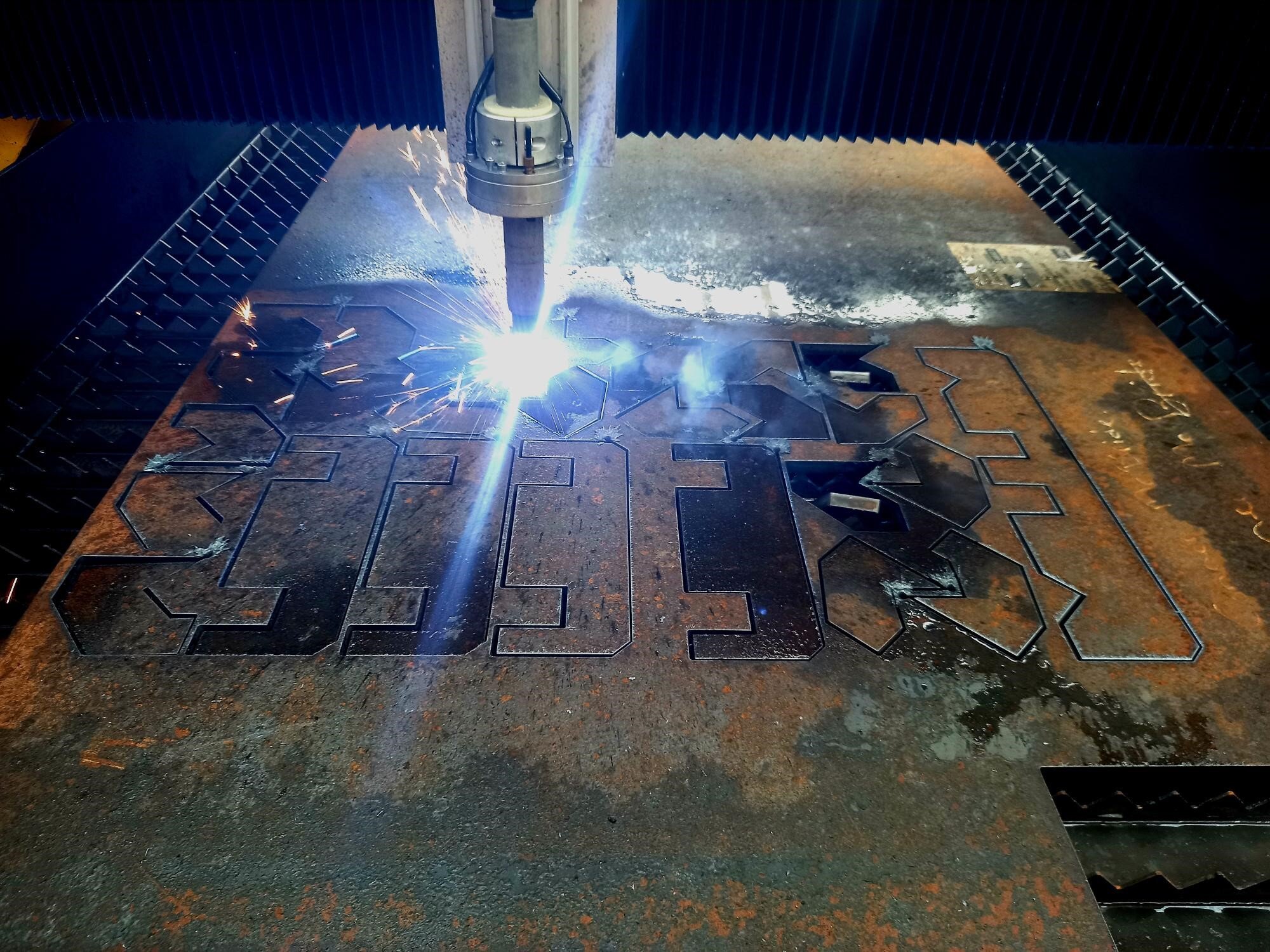

CNC Profile Cutting (Plasma & Oxy-Fuel)

Air Plasma Cutting

Arc Air gouging

Industrial Coatings services

Sandblasting and painting equipment complements the steel fabrication division, providing the ultimate in corrosion protection.

Project Management

Our project management team support our fabrication capability, providing:

Customer liaison

Contract planning

Subcontracts

Development and management of Health and Safety plans

Development and management of Quality Assurance plans

Reporting

Insurances and bonds

Contract claims and documentation

Design and CAD capability is available from our experienced design team. And, we also offer capacity in steam, hot water and two-phase pressure pipework and vessels, together with steam venting systems, pump evaluation and specifications for hot steam/water.

Our Fabrication Shop has been certified to ISO 9001:2008.

Additional information

Featured projects

Videos

Māori Innovation Awards HTTC

Genesis Tekapo A Refurbishment