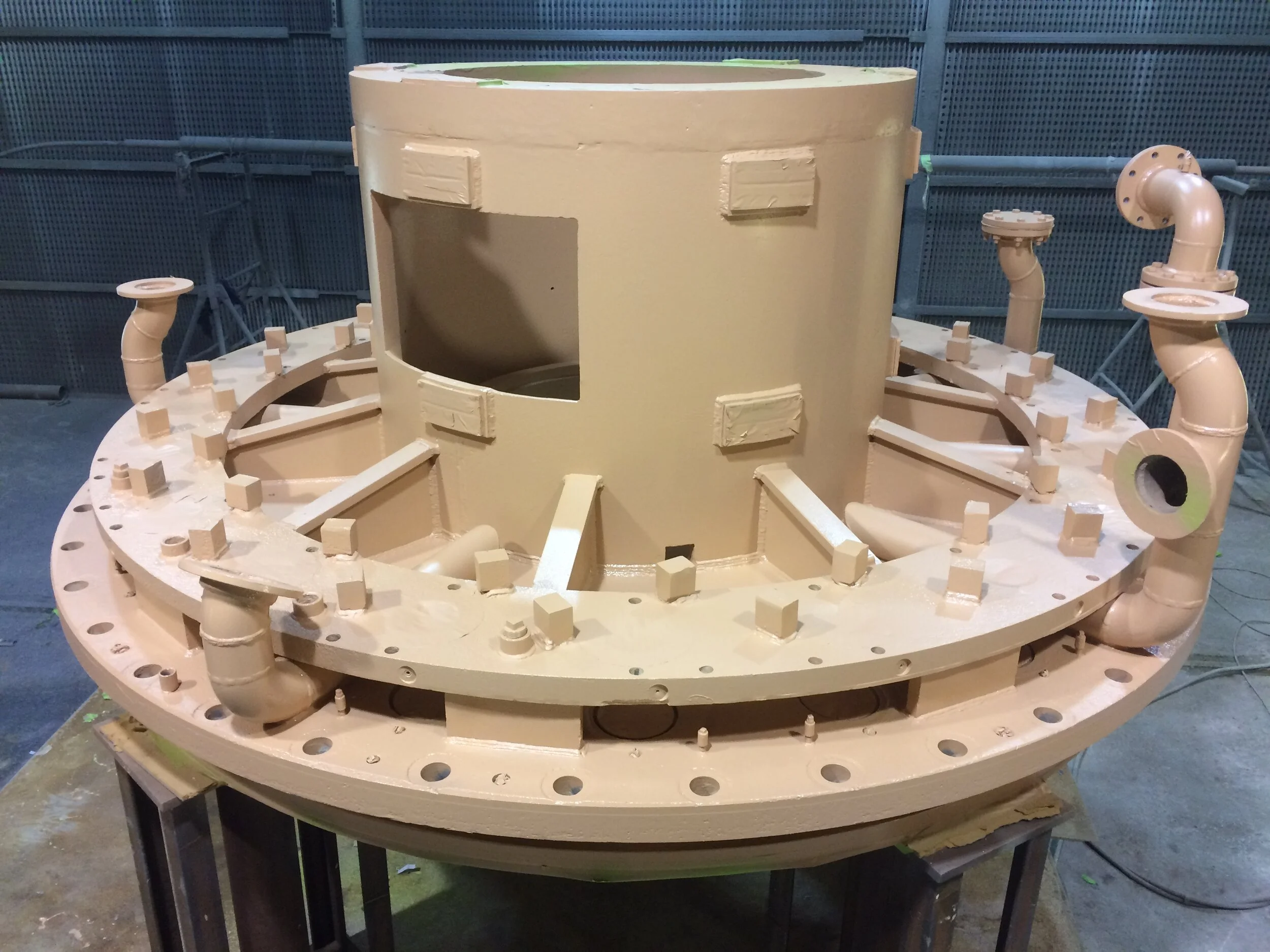

Industrial Coatings

We provide a modern sandblasting and painting facility at Wairakei, Taupo, which can be operated 24 hours a day.

We are accredited and compliant with ISO9001. All work undertaken in our sandblasting and painting facility complies with Sandblasting and Painting Management and Inspection procedures. And, all surface preparation is abrasion blasted to SSPC SP 10, or to client specifications.

The spray booth is compliant with the new advanced Australian Standard 4114 and has a floor area of 144m², making it one of the largest facilities available. It has been purpose-built and designed to accommodate large industrial items, with a 6 x 6m entrance. Heating is provided through a geothermal under-floor system that allows for all-weather coating.

The sandblasting facility is located directly behind the spray booth, connected by a railway track and trolley system, capable of carrying 30 tons. This layout allows for ease of movement of heavy objects during the blasting and coating process. The blasting booth also has a floor area of 144m² with geothermal under-floor heating and a working height of 6m.

We also offer a large storage area, measuring in excess of 1000m², to house equipment before painting and for curing after coating.

In addition to sandblasting, whether at our base or on your site, we also offer mobile soda blasting services. This process is well suited to delicate substrates and sensitive environments.

Capability

Site spray booth

We sandblast using a pressurised pot system supplied at 565 cfm. Our on-site facility is complemented by our mobile unit, which has the ability to deliver 295 cfm.

Mobile units

Two portable unit options are available. The first is arranged on a 12-ton truck complete with a 4.5-ton hiab. This ensures we can manipulate items on-site, as they are sandblasted and painted. The second unit is a smaller 4.5-ton crew-cab truck, suitable for smaller on-site blasting and painting jobs. Two mobile crews can run simultaneously for larger projects, one as a blasting unit and the other as a painting unit.

Site spray booth sensitive environments

We also have the ability to sandblast in environmentally sensitive sites, with the use of vacuum blast equipment. This equipment has zero discharge to the atmosphere. Full containment systems can also be provided for large scale operations.

Airless spraying

Painting is predominantly undertaken using a conventional spray system. However, airless spray equipment is also available if required.

Products

Altex Coatings is our primary product supplier for our heavy industrial coatings because they are the market leader and number one supplier of industrial coatings in New Zealand. All our coatings applicators are Altex trained and authorised.

Additional information

Commercial automotive painting

We can also provide a highest possible quality, commercial, automotive refinishing service.

People

Our people pride themselves on their high-quality workmanship and use best practice processes and leading industry techniques. Our goal is to provide long-lasting coating solutions, and we continually search for new innovations and product developments within our industry.

Products

The products we use are selected for their superior performance and quality. There is no substitute for this; each product range has a specific application purpose and is used to the standard set by the manufacturer. We work closely with key paint suppliers Altex Coatings and Resene Santano. Altex Coatings is the market leader and number one supplier of industrial coatings in New Zealand. Resene Santano is a key supplier of innovative solutions to the commercial automotive field.

A range of blast media is available, including B and C grade Garnet, to cover a wide range of blasting applications and profiles for all industrial and commercial finishes. In addition, Aluminium Oxide, Soda Blasting and high-pressure water blasting are also available.

Facilities

Our spray booth exceeds the new AS 4114 standard for spray coating applications. It has a floor area of 144m² which is heated using a geothermal underfloor system. The blast shed is located directly in line with the spray booth to allow seamless integration of projects from one area to the next. The blasting facility also boasts a large floor area of 114m² with an inbuilt Syntech garnet recovery system. Both facilities have a trolley system engineered to withstand a 30ton load.

Quality control

We use two quality control systems. The first is covered by the ISO 9001 accreditation. In-house quality assurance is achieved by using a standard procedure manual covering all aspects of coating applications. The second is the use of an independent inspector. The paint manufacturer produces a specification, and then spot inspections are carried out throughout the entire project. On completion, a full report is produced and provided to the customer.

Featured projects

Videos

Māori Innovation Awards HTTC

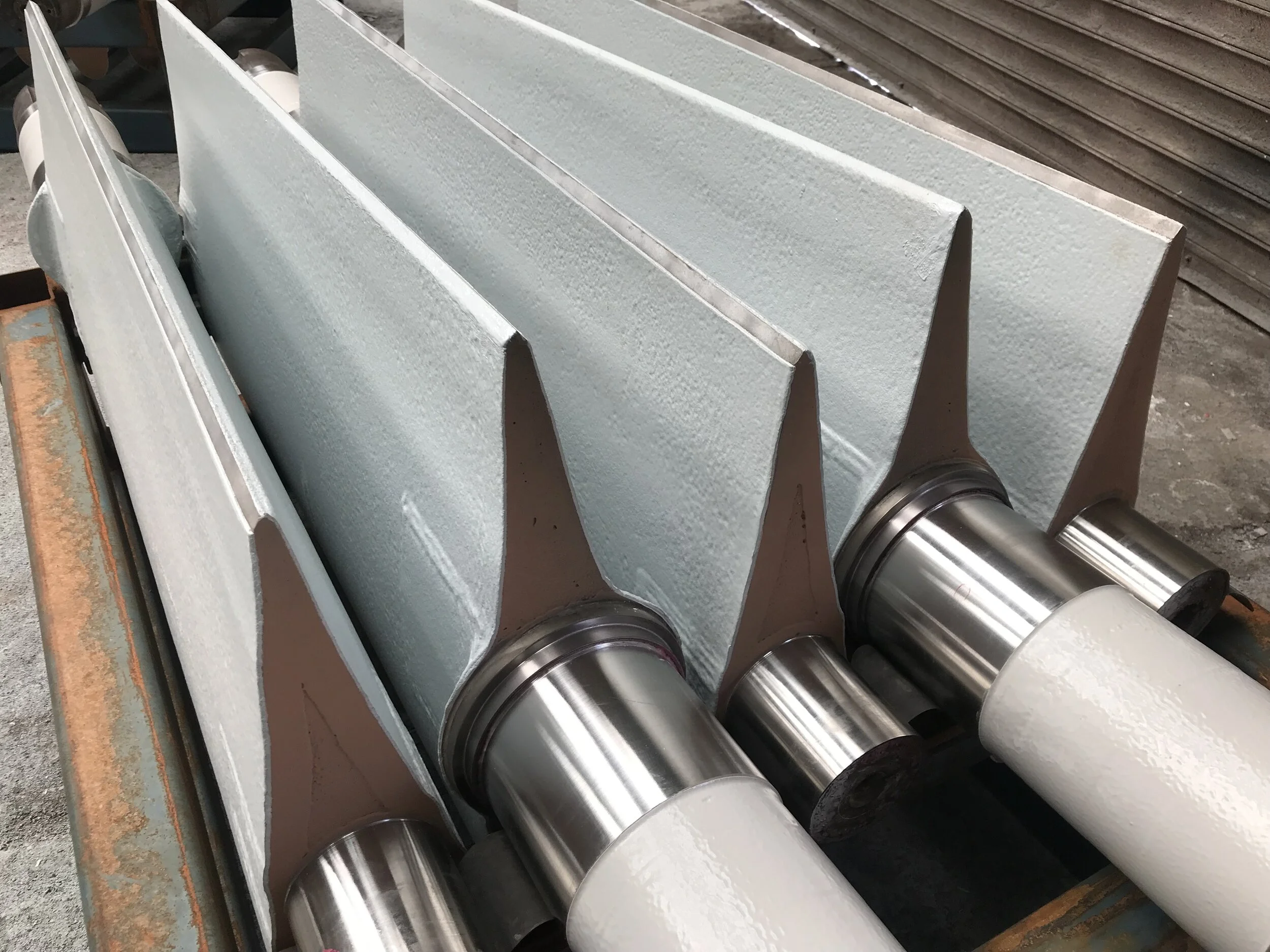

Genesis Tekapo A Refurbishment